Table of contents

What is the difference between DTF and UV DTF?

DTF (Direct to Film) and UV DTF (UV Direct to Film) are two popular transfer printing methods widely used in clothing, gifts, and custom products. Although their names sound similar, they differ greatly in materials, printing process, and where they are used.

1. DTF Process

Step 1: Print the design on the film using DTF ink (usually with white ink at the bottom)

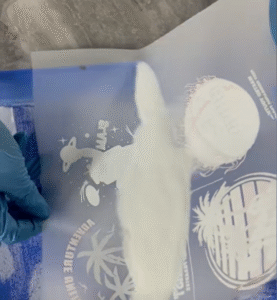

Step 2: Apply hot melt powder to the printed film while the ink is still wet.

-

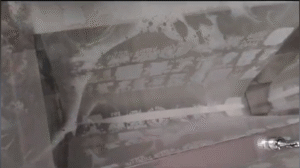

- Manually apply hot melt powder and heat to cure

heat to cure

- Use an automatic powder shaker and heat to cure

Ensure thorough and even agitation and heating

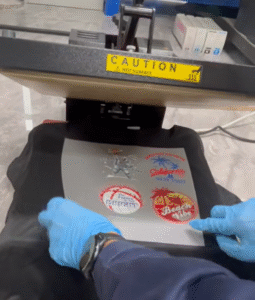

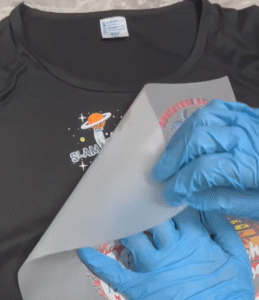

Step 3: Heat the film to melt the powder, then transfer the design to the fabric using a heat press

2 UV DTF Process

Step 1: Printing

Utilizing the AB film technology, the design is sequentially printed onto the A film in the following order:

white ink → color pigment → varnish (glossy coating)

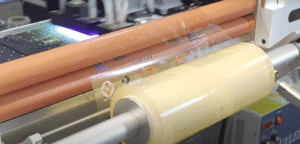

After printing, the B film, which is pre-coated with a heat-activated adhesive layer, is applied to the printed surface on the A film to laminate and encapsulate the design.

Step 2: Final Transfer

3 Applicable Scenarios

| Item | DTF | UV DTF |

|---|---|---|

| Applicable Materials | Various fabrics, T-shirts, canvas bags, cotton/polyester blends, and other flexible textiles | Glass, metal, plastic, leather, wood, phone cases, cups, and other smooth hard surfaces |

| Shape Requirements | Flat and flexible surfaces | Flat or slightly curved hard surfaces |